Cold Chamber Die Casting Machines Features

1. Tie rod type injection unit, easy to adjust and long lasting

2. High performance three phase injection system to easily produce complex castings

3. Advanced PLC control, reliable and easy to maintain

4. Quality double vane pump to improve productivity and energy saving

5. Independent piston type accumulators for fast speed injection and intensifier to ensure exact injection speed with stable and powerful intensification

6. Automatic die height adjustment, precise and simplified adjustment procedure

7. High grade external suction filter to ensure a clean hydraulic system and reduce the part damage and wear

8. Centralized electrical lubrication system to extend work service life of moving toggle joints under perfect lubrication

9. Components from famous international brands to ensure quick and easy service

Main Characteristics:

1. High performance injection system. Empty injection speed ≥ 8m/s, pressure setup time≤ 20m/s.

2. We choose pressure and flow sensors and proportion valves to ensure variable speeds and pressures adjustment continuously. (picture 1)

3. Choosing imported electrical ruler for controlling die open, die close stroke, ejection stroke to ensure the precise, exact and convinence control. (picture 2)

4. Perfect mold adjustment construction. Hydraulic motor drives the gear to adjust the mold automatically. (picture 3)

5. Choosing electric proportional valves to control pressure and flow. (Picture 4)

6. The hydraulic system chooses fliter ways with two grades to ensure the oil cleanning in hydraulic system so as to ensure the hydraulic valves works normally. (Picture 5)

7. Choosing automatic centralized lubrication system. The distributor, lubrication failure alarm devided to ensure the good lubrication. (Picture 6)

8. Siemens PLC. (Picture 7)

9. It can show and store shooting speed curve, pressure curve and displacement curve. It also holds two functions as machines state monitoring and malfunction diagnosing function. (Picture 8)

10. Draw multi-core devide, program design, dynamic simulation, scheduled to die insert and core pulling out action sequence can be independently set, the core pulling device can be used alone or together, the program can be any complied.

11. There are many safety devices in the die-casting, such as electrical appliance safety device, hydraulic pressure lock and all sorts of safety devices according to CE active standard.

12. There is oil level filter, oil temperature level filter, oil feed filter and oil oversized protection device in die-casting machine.

13. Safety door. It will be stopped automatically at once if there is someone touch it.

14. There is large rod hydraulic pumping unit over the operating panel, it is safety and quick to load the big mold.

15. Hydraulic pressure parts and electric apppliance parts all supplied by Parker, Rexroth, Tokimec, Yuken, Siemens, PRO-face.

16. We provide the auto ladler, auto sprayer, auto extractor, furnace, molds etc, according to your requirements.

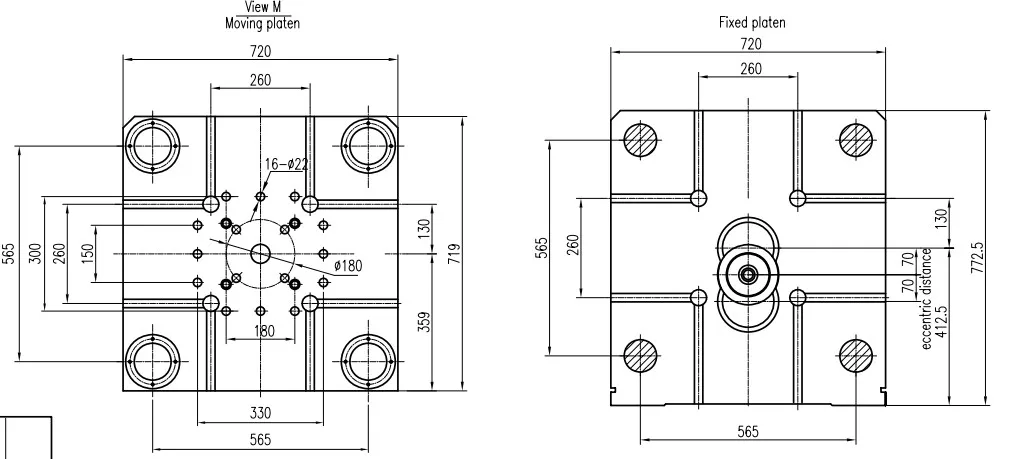

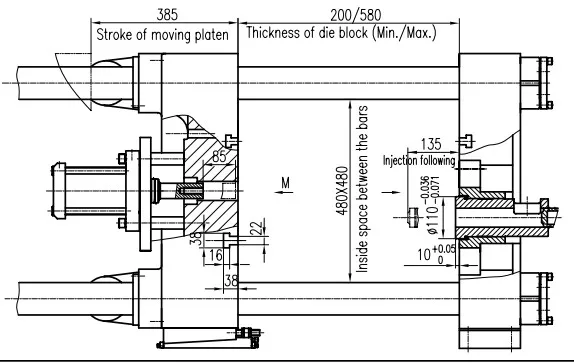

| The project | The unit | J1118K | |

| Die locking force | KN | 1800 | |

| Size of moving platen(HxV) | mm | 720X719 | |

| Inner space between the bars(HxV) | mm | 480X480 | |

| Thickness of die block(Min./Max) | mm | 200/580 | |

| Stroke of moving platen | mm | 385 | |

| Ejection sroke | mm | 85 | |

| Ejection force | KN | 109 | |

| Injection force | KN | 230 | |

| Injection stroke | mm | 350 | |

| Injection Position | mm | 0,-70,-140 | |

| Dimeter of shot sleeve | mm | 50 | 60 |

| Dosage of fluid metal per shot (AL) | kg | 1.3 | 1.9 |

| Injection pressure | MPa | 117 | 81.3 |

| Max.Projecting area of casting | cm2 | 221 | |

| Dry cycle | s | 7 | |

| Pipe line pressure | MPa | 13 | |

| Motor power | KW | 15 | |

| Machine weight | kg | 7000 | |

| Overll dimensions (LxWxH) | mm | 5600x1280x2560 | |

The chart of die mounting

Hot Tags: 180ton high performance large cold chamber die casting machine, China 180ton high performance large cold chamber die casting machine manufacturers, suppliers, factory